Sideboard trailer is a multi-purpose vehicle that is specially designed for the carriage of goods. It has been widely applied in the fields of logistics, building and agriculture because of its flexible design and high efficiency. In this paper, we will introduce the advantages of the sideboard trailer from the various parts.

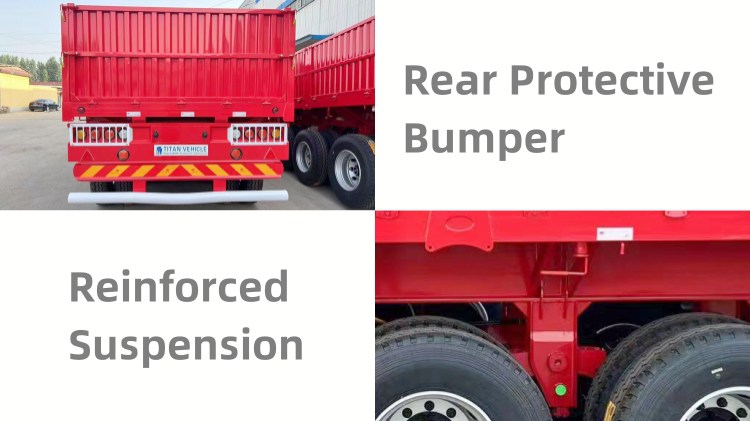

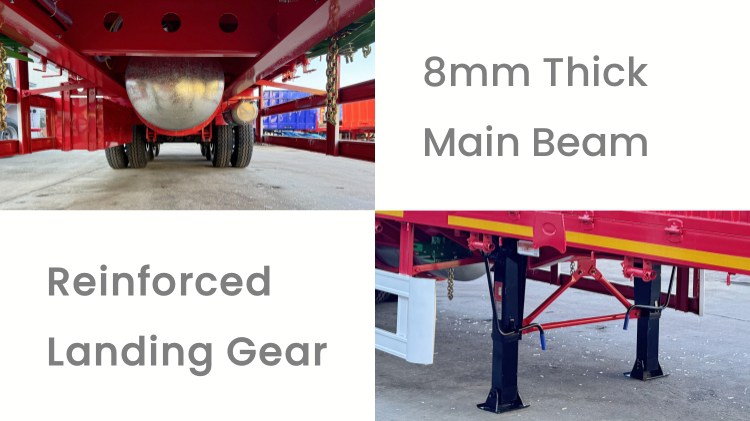

The chassis of a trailer with side walls is generally made of high strength steel. The main beam with a thickness of 8 mm ensures the stability and carrying ability of the trailer with side walls.

The frame is strong and light, able to bear a lot of weight. The polyurethane coating helps the trailer with side walls to withstand the effects of bad weather and complicated road conditions. The robust frame also reduces maintenance costs and improves the lifetime of the trailer side wall. This allows companies to feel more secure during transportation.

Sideboard Trailer with Side Walls in Mozambique

Sideboard Trailer with Side Walls in Mozambique

Sideboard Trailer with Side Walls in Mozambique

Sideboard Trailer with Side Walls in Mozambique

Model: Sideboard Trailer with Side Walls in Mozambique

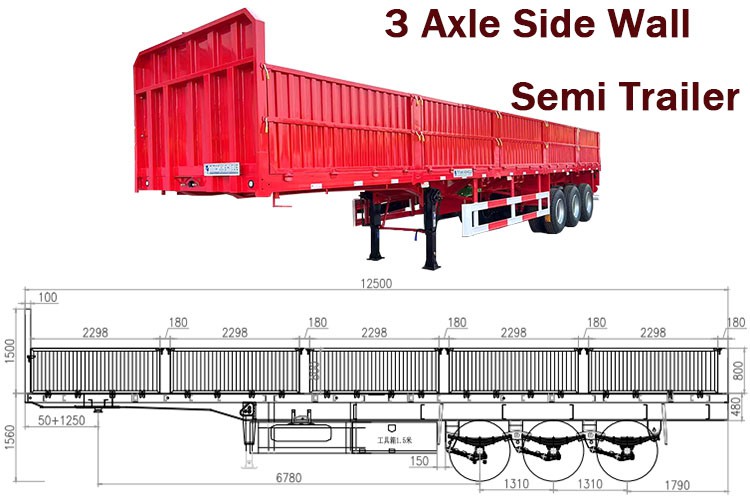

Tare Weight: About 7.6T

Dimension(mm): 12500x2800x3260mm(depends on final design)

Loading capacity(ton): ≤60T

Axles: 3 axles, 13T/16T ,FUWA/ BPW/ TITAN Brand

Tire: 12 units, 12.00R22.5 or 315/80R22.5

Rim: 9.00-22.5 or 9.75-22.5

Suspension: Mechanical suspension

Color: optional

1. Sideboard

Sideboard is a key part of a trailer side wall. It is cleverly designed so that it can be flexibly transported in a variety of shapes and sizes. The sideboard adopts Q345 high strength structure steel, lightweight and durable. Therefore, it can effectively prevent the cargo from slipping and overturning in the course of transportation in Mozambique. Meanwhile, the height of the sideboard can be adjusted to meet the needs of different cargo so as to increase the adaptability of the transport.

2. Chassis

The chassis of a sideboard trailer is designed to absorb shock and stabilize in Mozambique. It is often fitted with a highly effective suspension system. The base plate with a thickness of 3 mm is used to disperse the concentrated load. It is applicable to the transportation of all kinds of goods, including heavy machinery, building materials and bulk goods. The design not only improves the ride comfort, but also extends the lifetime of the sideboard trailer. It is applicable to all kinds of road conditions in Mozambique.

3. Tires

Trailer side walls are fitted with high performance tyres, often with wide tires to improve contact and grip. The design can efficiently distribute cargo weight, reduce road stress, and enhance the vehicle's stability and handling. In complicated traffic conditions, high quality tyres can guarantee the safe driving and decrease the chance of accidents.

4. Braking system

Safety is paramount in transport operations in Mozambique. Wider brake pads provide a more even distribution of pressure during braking. At high speed, a 224mm wide brake pad can effectively prevent the trailer side wall from slipping or turning. Modern braking systems also have a number of safety protections. This reduces the risk of brake failure on a trailer side wall and improves overall safety in Mozambique.

5. Quick loading and unloading

The flexible design of the flatbed truck not only improves the loading and unloading efficiency, but also reduces the labor cost. Adjustable railings make it convenient for forklifts and other facilities to quickly load and unload various items. This kind of high efficiency handling capacity is especially applicable to busy logistics centres and ports, which can satisfy the demand of quick turnover.

6. Flexible cargo fixing methods

The trailer with side walls design allows for a variety of cargo fixing methods. Such as using ropes, chains or special clamps. This variety of fixing methods ensures the safety of cargo during transportation in Mozambique. It also avoids losses caused by bumps and movement. At the same time, the flexible fixing scheme can adapt to cargo of different shapes and sizes, improving the safety of transportation.

7. Rope tensioner design

Rope tensioners are usually made of high-strength steel. It owns good durability and corrosion resistance. Its design generally adopts mechanical structure, including:

Lock mechanism: allows users to easily adjust and lock the tension to adapt to cargoes of different shapes and sizes.

Adjustable performance: Many rope tensioners adopt a sliding design. Users can freely adjust the strength and length according to actual needs.

Easy operation: Rope tensioners are usually easy to operate in Mozambique. And users can quickly tighten the rope manually or electrically, saving loading and unloading time.